Natural Refrigeration: The Mechanical Engineers' Role towards driving Indian space cooling towards Sustainability

Updated on: 06 June, 2025

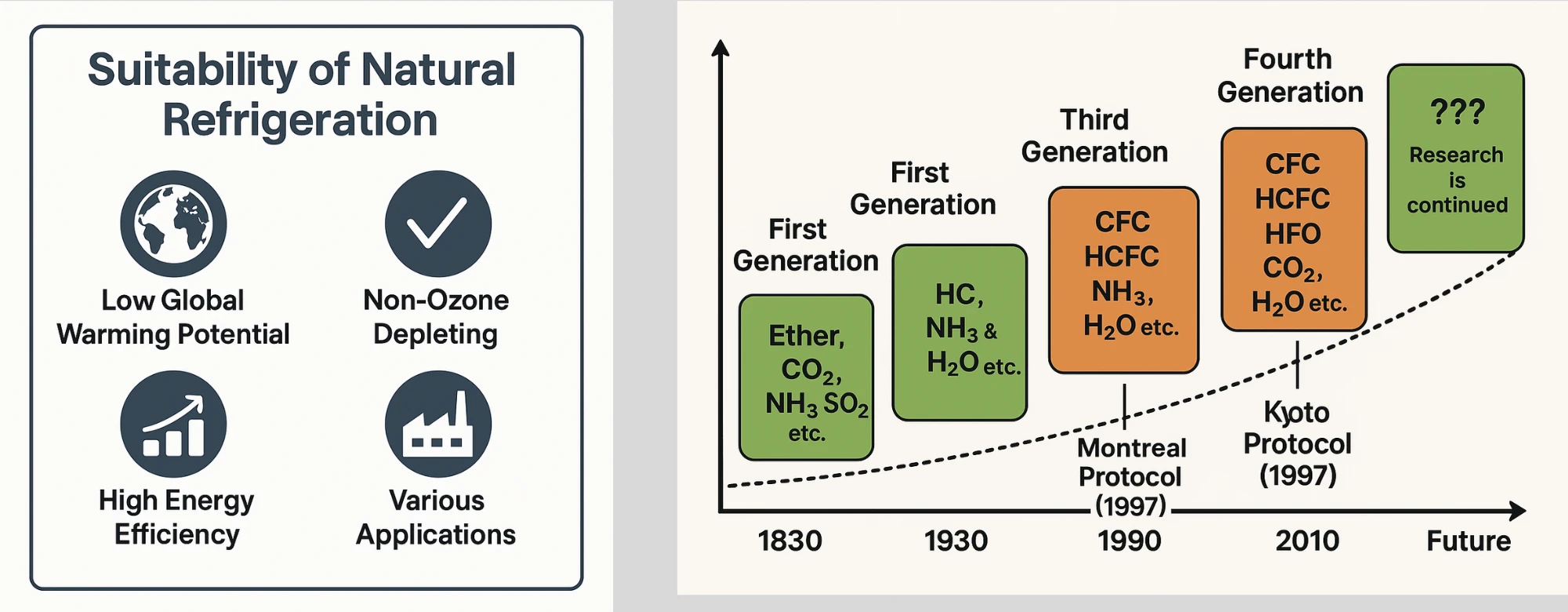

The world at present needs to be cooled—either for refrigeration, thermal comfort, medical uses, or data centers. India, with its tropical environment and rapidly expanding economy, is constantly in need of more and more refrigeration. But conventional cooling technologies based on man-made refrigerants like HFCs (Hydrofluorocarbons) and CFCs (Chlorofluorocarbons) have produced hazardous environmental impacts because they have a high Global Warming Potential (GWP) along with an Ozone Depletion Potential (ODP).

Mechanical engineers are at the intersection of the corner where traditionalism meets thermodynamics. Natural refrigerants—materials like carbon dioxide (CO₂), ammonia (NH₃), and hydrocarbons (R-290, R-600a)—are changing our minds about cooling technology.". The refrigerants have improved thermodynamic performance, reduced environmental effect, and enormous opportunities for energy efficiency.

Why India Needs Natural Refrigerants?

- Environmental Mandates: India is a signatory to the Kigali Amendment to the Montreal Protocol (Location: Kigali, Rwanda, Effective: January 1, 2019), with the goal of phasing down HFCs. Natural refrigerants are at the heart of fulfilling these international commitments.

- Climate Resilience: Climate Resilience: Being in operation at temperatures above 45°C during peak summer months in most geographies, the cooling equipment must be energy efficient and climate resilient. CO₂ transcritical systems, for example, are in progress to design for high ambient conditions with promising performance.

- Expansion of Cold Chain Infrastructure: From medicine to agriculture, India's cold chain is expanding at an unprecedented scale. Natural refrigerants are most appropriate for cold storages, especially ammonia-based systems, which are more thermodynamically efficient.

- Energy Security: Energy-saving refrigeration directly reduces electricity consumption, which de-stresses India's grid and reduces dependence on fossil fuels.

The Boom of Natural Refrigeration Technologies in India

India’s HVAC and Refrigeration industry is based mainly on synthetic refrigerants, which is a major source of greenhouse gas emissions. As a result of an Indo-Norwegian project (INDEE+), aimed at proving the feasibility of natural refrigerants in India through three pilot systems.

- 140 kW Transcritical CO₂ (R744) Heat Pump for a School Kitchen (Bengaluru): Commissioned to substitute a diesel boiler at Akshaya Patra Foundation, this system provides hot water (up to 90 °C) for cooking and chilled water (7 °C) for cooling simultaneously. Simulations of comparison between direct expansion and ejector-assisted modes reveal that the ejector mode enhances overall COP by 6%, with improved efficiency and greater operating flexibility.

- 350 kW R744/R717 Cascade System for Seafood Processing (Kochi): Commissioned at NAS Fisheries, the system functions well at -42 °C for seafood freezing with the use of CO₂ and ammonia. A COP of 1.40—better than traditional two-stage R717 systems—was achieved and risk from ammonia close to food areas was minimized by continuous monitoring over a week.

- 30 kW Propane (R290) On-Board Ice Maker for Fishing Boats: The system is designed to make ice blocks onboard and is more efficient than R404A and R407A systems because of the larger latent heat of R290. Simulation studies led to the optimization of heat exchangers and compressor conditions.

This project highlights the technical and environmental benefits of natural refrigerants and seeks to establish local capability and promote uptake throughout India's HVAC&R sector.

Mechanical Engineering: The Heart of Refrigeration Systems

Mechanical Engineering occupies a key position in the design, operation, and development of refrigeration systems and, therefore, is the real heart of the technology. Refrigeration is vital to food preservation, making air conditioning possible, facilitating medical and industrial processes, and contributing to increased comfort and safety in modern living.

- Thermodynamics and Heat Transfer

- Component Design and Development

- System Integration and Optimization

- Material Selection and Manufacturing

- Sustainability and Innovation

- Research and Development

Conclusion

Mechanical Engineers do not merely construct refrigeration systems—they drive them, making them efficient, safe, and environmentally friendly. With changing technology and climate requirements, their function becomes all the more essential in redefining the world's cooling.

Written By:

Chayan Das

Department of Electronics & Communication Engineering