From Code to Creation: Why CSE Graduates Need 3D Printing Expertise

Updated on: May 05, 2025

The integration of computer science and 3D printing has made a significant change to various industries, most prominently to the medical industry, where personalized medicine/personalized informatics, surgical planning, prosthetic generation and many more. Computing methods allow the professional to customize a medical solution with the aim of improving patient outcomes.

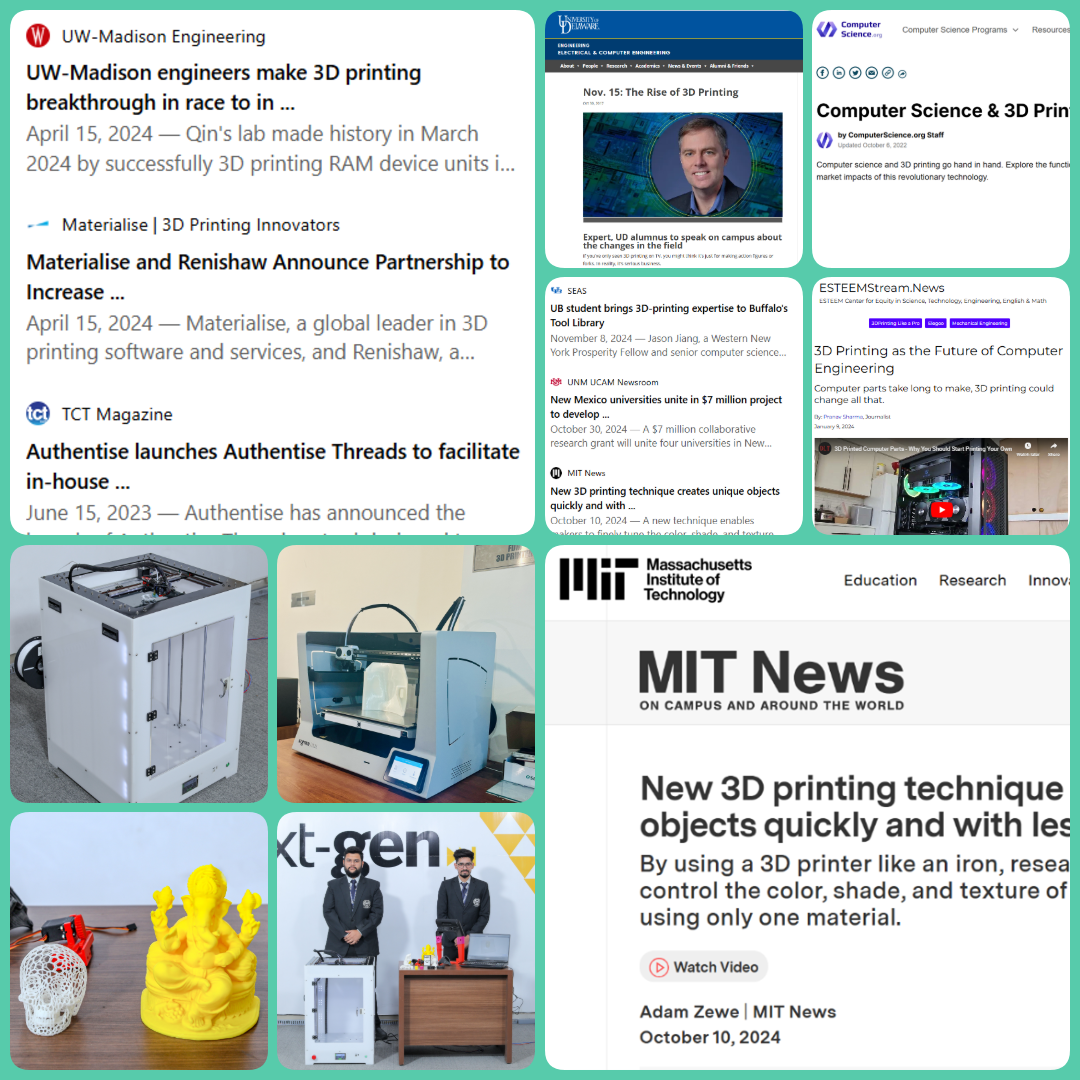

State-of-the-Art 3D Printing Facility at SGT University’s Mechanical Engineering Department

The Department of Mechanical Engineering at SGT University is well equipped with 3D printing facility, providing a conducive environment for students and researchers to engage with updated additive manufacturing technologies. Rapid prototyping, custom manufacturing for parts, and testing of innovative designs across applications are made possible by this facility. The 3D printing lab accepts academic projects, research work, and industry collaboration, thereby facilitating practical learning as well as engineering advancements.

Advancements in Medical Imaging, 3D Printing, and AI for Personalized Healthcare

Modern medical imaging techniques, including various imaging modalities like CT scan and MRI, provide high-resolution images that are consequently interpreted by sophisticated algorithms to generate accurate 3D anatomical models of organs, bones, and tissues. AI and Machine Learning facilitate improved image segmentation and detection of anomalies with the result that models are retained with utmost accuracy. Custom prosthetics and implants are designed using CAD software, which runs simulations to optimize durability and efficacy. The emergence of patient-specific anatomical models through 3D printing further allows surgeons to accurately plan and rehearse complex procedures.

Bioprinting is an advanced application of medicine-using 3D printing to create structures resembling tissues, enabling organ transplantation. Bioprinting controls the deposition of bio-ink algorithmically, modelled with predictive behaviour of cells to build tissue-like structures. Compounding this, AI computational modelling assists in drug development, optimizing the molecular structure, and predicting drug interactions more rapidly than conventional means. With preoperative planning through 3D-printed anatomical models, surgeons are given an opportunity to rigorously rehearse complex procedures.

Generative Design and Digital Twins: Revolutionizing Engineering with AI and Cloud Computing

Generative design uses computational algorithms that enable engineers to design highly complex structures that are lightweight and durable. Printing parameters can be optimized using machine learning models to eliminate errors and enhance material utilization. Cloud computing can then facilitate manufacturing processes so that remote monitoring and control will ensure seamless global teamwork. Thus, digital twins embody a technology that creates virtual replicas of physical components, thereby supporting predictive maintenance such that potential failures may be detected before they happen.

AI-Driven Automation and Additive Manufacturing: Transforming the Future of Production

Automation-driven robotic systems further benefit advanced manufacturing, taking precision assembly, inspection, and defect detection to an upgraded level of performance for production lines. Smart sensors and AI analytics detect inefficiencies within the manufacturing processes, allowing for real-time corrective actions leading to increased production and energy savings. Techniques of industrial additive manufacturing, including direct metal laser sintering (DMLS) and electron beam melting (EBM), are readily available for the manufacture of complex metal components for aerospace, defence, and automotive applications.

These technologies provide manufacturers with the flexibility to manufacture parts that are lightweight, yet extremely durable, thereby taking full advantage of reduced material waste, which results in cost and sustainability. The future of computer science in 3D printing seems destined for enhanced achievement owing to the AI, cloud computing, and real-time data-processing-based high-tech innovations that are currying the way yet.

AI-Powered Disease Prediction and Personalized Healthcare Innovations

In the realm of disease prediction and early diagnosis, AI is proving to be a strong pillar. With advanced machine learning algorithms detecting aberrant patterns and creating risk factors by sifting through huge amounts of information, including but not limited to medical history, genetics, and imaging scans, the predictive analytics formed via AI would enable the doctor to prepare the groundwork for an early diagnosis of the disease, hence affecting treatment outcome and survival of the patient.

Herein, AI-based diagnostic technology may work in conjunction with 3D printing to create personalized medical devices that include prosthetics, implants, and tissue scaffolds tailored to an individual’s specific needs. Wearable sensors that can monitor health care on an AI platform will enable real-time updates on a patient’s health and setting off proactive intervention to achieve personalized treatment plans.

Revolutionizing Industries with AI-Driven 3D Printing and Computational Design

Outside the confines of medicine, the interplay between computer science and 3D printing is stirring transformational change in many industries. In manufacturing, process optimization using AI increases efficiency, minimizes material waste, and applies generative algorithms to generate lightweight designs with high structural integrity. In architecture and construction, 3D printing is employed to manufacture building elements and even whole buildings-with a very favourable impact on cutting down the costs of materials and construction time.

Computational simulations optimize the performance of 3D-printed components in automotive and aerospace uses, leading directly to more fuel-efficient vehicles and aircraft. The fashion industry uses 3D printing for custom apparel, shoes, and accessories, allowing designers to work with complex patterns and sustainable materials. In 3D printing, computer-aided design nurtures creativity and innovation within education by providing students with the ability to develop physical prototypes of their ideas. Given the advancement in AI applications, software engineering, and real-time data analytic applications, 3D printing will forever alter things in almost every industry, thus setting the next stage for design, manufacturing, and technological advancement.

The fusion of computer engineering, artificial intelligence, and automation in industrial operations ought to remain steady and further nurture advancement in manufacturing. In an Industry 5.0 environment, the utilization of cyber-physical systems will continue to enhance the capabilities of interconnected manufacturing networks, enabling increased flexibility and scalabilities in production. Blockchain technology will most probably find its way into supply chains, ensuring transaction security and traceability of components. With continuous innovation, this fusion between computer engineering and advanced manufacturing will be the mainstay for achieving sustainability, efficiency, and mass customization in almost every sector of the economy.

Written By

Ms. Deepika Singh Singraur

Assistant Professor